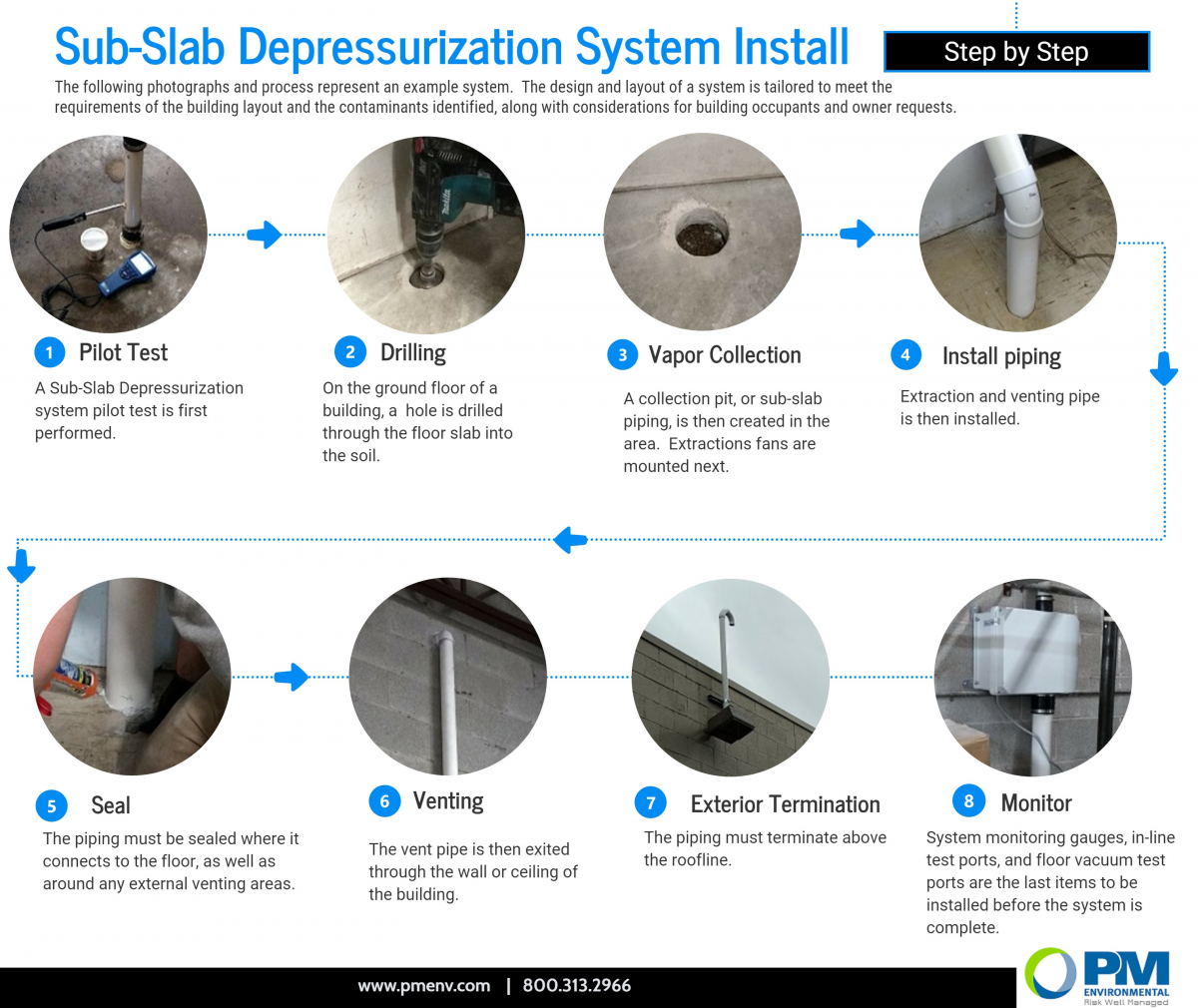

How is a Sub-Slab Depressurization System Installed? {Infographic}

As regulations increase across the country regarding evaluating vapor intrusion pathways, so too is the need for proper mitigation systems.

The first step towards properly mitigating vapor intrusion involves sub-slab soil gas sampling to identify the levels assess the potential risk.

If Vapor Intrusion is identified, and found to be above the screening levels, a mitigation system should then be put in place. For existing buildings where vapor intrusion is identified, the most common mitigation system is the Sub-Slab Depressurization System (SSD). SSD systems are used to mitigate indoor vapors arising from subsurface contamination.

The EPA defines SSD technology as “a system designed to achieve lower sub-slab air pressure relative to indoor air pressure by use of a fan-powered vent drawing air from beneath the slab.” Thus, even if there are holes, cracks, or other pathways between the building and the subsurface, vapors flow downward, not upward. Thus, a well-designed depressurization system prevents any toxic vapors from intruding above.*

See how this SSD system is installed:

*Source: http://www.cpeo.org/techtree/ttdescript/ssvd.htm

Publication Details

Date

January 9, 2018